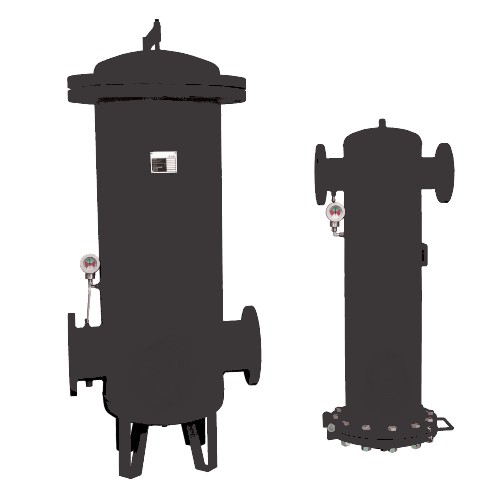

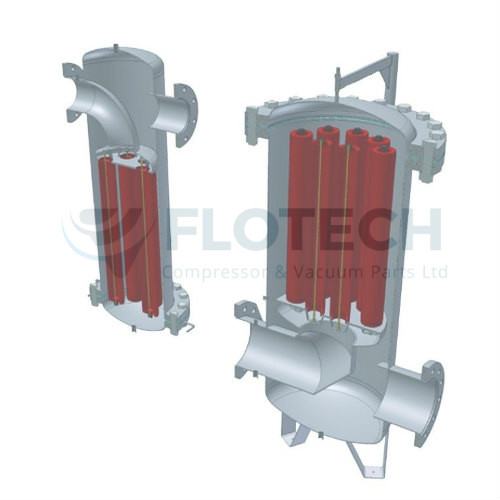

Description

BFFC filters are designed for protection of the downstream compressed air system and equipment against defects and other failures. Due to their robust welded carbon steel construction, are used for installation in heavy industrial applications with high air flows. They ensure high efficient removal of solid particles, water, oil aerosols, hydrocarbons, odour and vapours from compressed air systems up to 16 bar. Required compressed air quality according to standard ISO 8571-1 can be achieved with 6 different grades of filter elements (B, P, R, M, S and A). Optional external condensate drains should be used for efficient condensate draining from filter housing. Fluid group 1 on request.

Characteristics:

| Operating pressure | 16 bar |

| Volume flow rate | 1680 to 31400 Nm3/h |

| Connections | DN80 to DN300 |

| Operating temp. range | 1,5 to 65 °C |

| Standard colour | RAL 5012 |

Applications:

• electronics

• food and beverage

• chemical

• petrochemical

• plastics

• paint

| Filter Housing Size | Pipe Size | Max. Oper. Pressure | Flow Rate at 7 bar(g), 20 °C | |

| DN | bar/psi | Nm³/h | scfm | |

| BFFC 0240 | 80 | 16/232 | 1,680 | 989 |

| BFFC 0300 | 100 | 16/232 | 3,150 | 1,853 |

| BFFC 0450 | 125 | 16/232 | 4,700 | 2,765 |

| BFFC 0600 | 150 | 16/232 | 6,300 | 3,706 |

| BFFC 0900 | 150 | 16/232 | 9,400 | 5,530 |

| BFFC 1200 | 200 | 16/232 | 12,550 | 7,382 |

| BFFC 1500 | 200 | 16/232 | 15,700 | 9,235 |

| BFFC 1800 | 250 | 16/232 | 18,850 | 11,088 |

| BFFC 2500 | 250 | 16/232 | 25,100 | 14,765 |

| BFFC 3000 | 300 | 16/232 | 31,400 | 18,481 |

Dimensions & Mass

| Dimensions [mm] | Mass | ||||

| A | B | C | D | E | kg |

| 1170 | 450 | 1645 | 219 | 177 | 61 |

| 1340 | 560 | 1780 | 324 | 227 | 115 |

| 1340 | 560 | 1780 | 324 | 227 | 123 |

| 1425 | 620 | 1810 | 368 | 265 | 178 |

| 1480 | 680 | 1850 | 419 | 650 | 218 |

| 1835 | 792 | 510 | 508 | – | 320 |

| 1880 | 918 | 535 | 610 | – | 455 |

| 1950 | 955 | 555 | 610 | – | 500 |

| 2060 | 1042 | 645 | 711 | – | 590 |

| 2130 | 1085 | 680 | 711 | – | 684 |

Please note:

- B Filter element can be cleaned with ultrasonic bath or with back flushing. Interval of cleaning depends on application. If necessary replace filter element with new one.

- A Filter element should be changed periodically to assure proper quality of air, but at least every 6 months. Activated carbon filters must not operate in oil saturated conditions.

Correction Factors

| Operating pressure [bar] | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| Operating pressure [psi] | 29 | 44 | 58 | 72 | 87 | 100 | 115 |

| Correction factor | 0.38 | 0.5 | 0.63 | 0.75 | 0.88 | 1 | 1.13 |

| Operating pressure [bar] | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| Operating pressure [psi] | 130 | 145 | 160 | 174 | 189 | 203 | 218 | 232 |

| Correction factor | 1.25 | 1.38 | 1.5 | 1.63 | 1.75 | 1.88 | 2 | 2.13 |

Condensate Drains

Differential Pressure Indicator

Accessories